Pre-Engineered Steel Building

Our Pre-Engineered Steel Buildings are constructed in advance for your convenience with the most cost-effective steel construction solutions. We spare no expense in ensuring our building’s safety and structural performance. Our devotion to quality and safety is evident in every structure. Rest assured you’re in good hands with Britto Design and Development Ltd Steel sector.

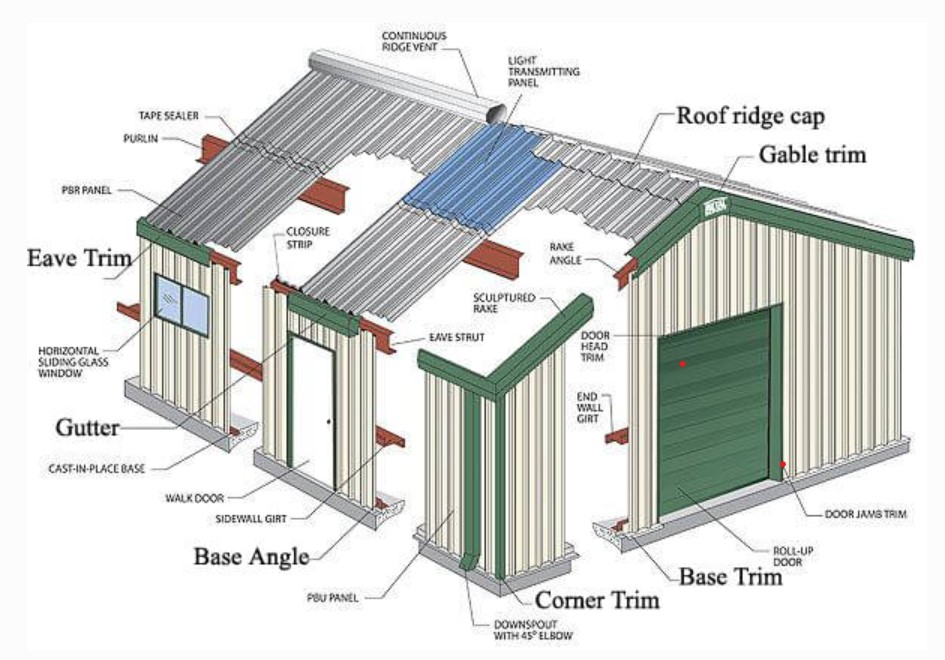

The PEB Steel Structure is made up of frames, secondary members (Cold Formed Members), steel standard buyouts, accessories, a mezzanine system, a crane system, thermal insulation, and wall and roof panels. Every structure undergoes thorough testing before leaving our facilities. We guarantee the peace of mind that will earn our customers’ loyalty.

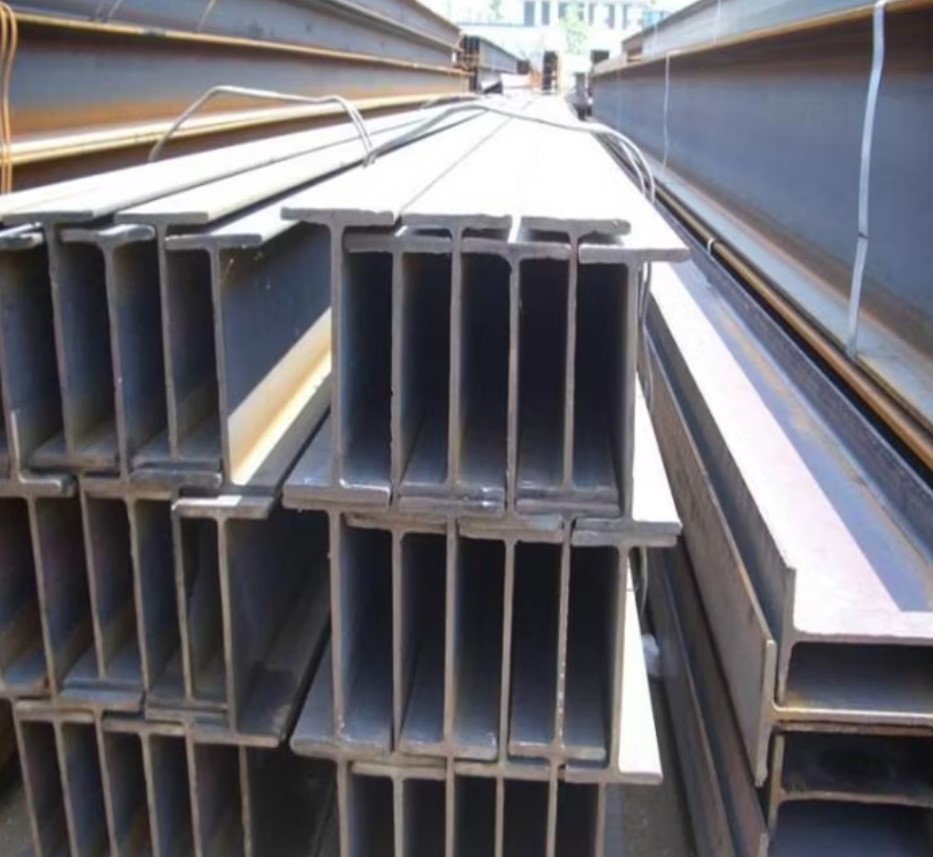

Secondary Members in the PEB industry refer mostly to the longitudinal roof and wall members that are roll-formed from galvanized coils or presses broken from narrow galvanized sheets. The raw material of these members is stocked in five thicknesses: 1.6, 2, 2.5mm.

The following building components are considered secondary members:

- Z” sections acting as longitudinal roof purlins and longitudinal wall girts that connect to columns & rafters and support the exterior roof and wall panels.

- “C” sections used purlin, framed openings, and as a transition member between partial block walls and wall panels.

- Eave struts located at the building eaves (corner of the roof and wall sheeting alongside walls also provide bracing for frames and support the roof and wall panels.

- The Mezzanine Deck (0.7mm thick) is used to support concrete slabs in second-level flooring. Base angles, gable angles, and mezzanine edge angles.

- These are items that are required in almost every PEB Steel Structure. They are manufactured by others and stocked by the PEB manufacturer. They include Anchor Bolts, Connection Bolts, Sag Rods, and Cable Bracing Components.

Our Submerged Welding machine makes the welding Fast, smooth, and monolithic.